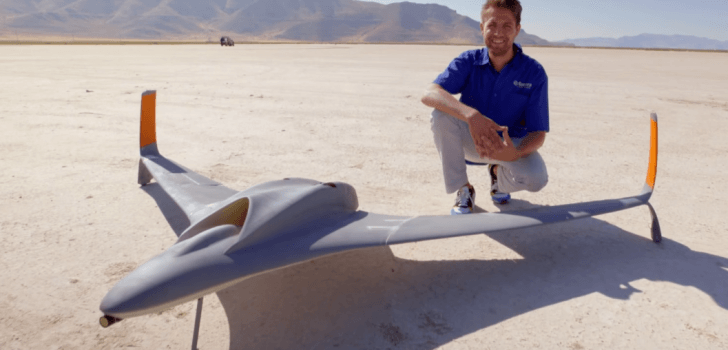

Engineers at Aurora Flight Sciences and Stratasys Ltd. have managed to create an unmanned aerial vehicle using 3D printing technology. The aircraft can reach speeds of up to 150 mph, and it represents the largest and most complex unmanned aerial vehicle ever created using 3D printing. The aircraft was unveiled earlier this week at the Dubai Airshow.

Aurora was responsible for designing the aircraft, while Stratasys was in charge of the manufacturing. The aircraft has a wingspan of 9 feet, and it only weighs 33 pounds. More than 80% of the plane was created using the 3D printing process of Fused Deposition Modelling. This process enables large objects to be created at particularly low weights.

The fuselage of the plane is made of nylon, and the engine exhaust pipe was 3D printed in metal. This was so that it could withstand the high temperatures of the exhaust fumes.

According to the companies, the primary goal of the project was to showcase the possibilities of quickly designing and producing a lightweight aircraft that can be flown quite easily. The part of the plane that took the longest to print was the fuselage, which took about nine days to produce. Other components only took anywhere from a few hours to a few days.

It took slightly more than a month from assembly for testing to initiate. Engineers from Stratasys have said that everything worked properly, and test flights were successful. The company now believes that it could build a second plane in the time of just two to three weeks.

Other unmanned aerial vehicles have been created in the past using 3D printing. In April of last year, the University of Sheffield’s Advanced Manufacturing Research Center managed to produce an airframe of an unmanned aerial vehicle. This airframe was able to be printed within a single day. Later that year, the researchers added electric motors that made the aircraft capable of reaching speeds of up to 45 mph.

Stay Connected